Automatic disposable medical face mask masking machine is universal design for the production of non-woven Multi-layer face mask, it is mainly constructed by material feeding, shaping and welding, die cutting/forming, transmission, ear loop welding and stacking mechanism. Except materials loading to be done by manual, other functions are fully automatically run. It is also could be combined with one, or two ear loop sealing welding stations to setup a line which depends on line speed requirement or your production output requirement.

1.Mask Making Production Specification

|

Item |

Semi-automatic Solution |

Automation solution 1+1 |

Automation solution 1+2 |

|

Solution NO. |

HY-C0/C01 |

HY-C1 |

HY-C2 |

|

Equipment demension |

L5100*W3800*H2000mm |

L5100*W3800*H2000mm |

L7000*W3800*H2000mm |

|

Site requirements |

8000*5000mm |

8000*5000mm |

9000*4500mm |

|

Max.power |

18KW |

20KW |

29KW |

|

Air Pressure |

0.5-0.6Mapa |

0.5-0.6Mapa |

0.5-0.6Mapa |

|

Output efficiency |

30-40 Pcs/min. |

30-40 Pcs/min. |

60-80 Pcs/min. |

|

Operator requirement |

2/3 |

2 |

3 |

|

Delivery time |

7-10 days |

10-14 days |

10-14 days |

2.Structure Specification

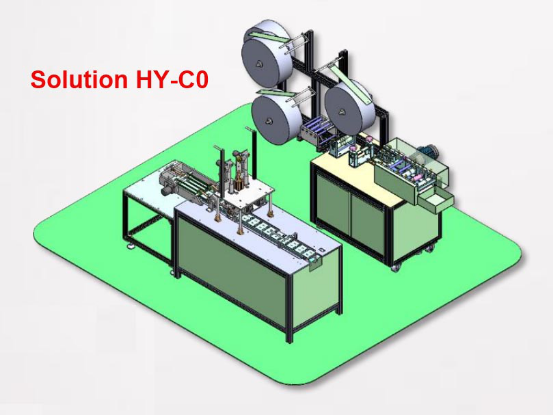

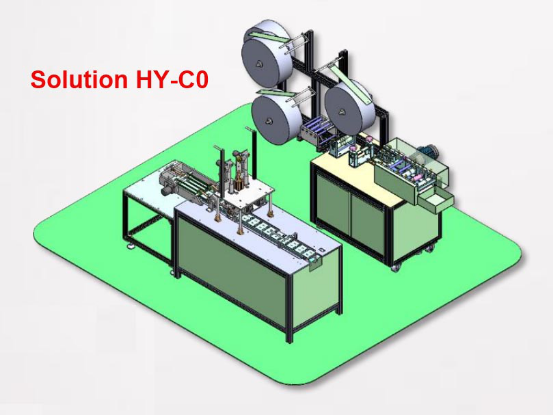

Semi-automatic solution: HY-C0

Total include:

1 sets of automatic mask manufacturing machine FM series

1 sets of semi-automatic ear loop welding machine FW series 02

Room size: 8000*5000mm

Total need 2 operators,one people for loading and unloading,another people welding operation

Output efficiency:10-16 PCS/minute

Semi-automatic solution: HY-C01

Total include:

1 sets of automatic mask manufacturing machine FM series

1 sets of automatic ear loop welding machine FW series

Room size: 8000*5000mm

Total need 3 operators for loading and unloading

Output efficiency:30-40 PCS/minute

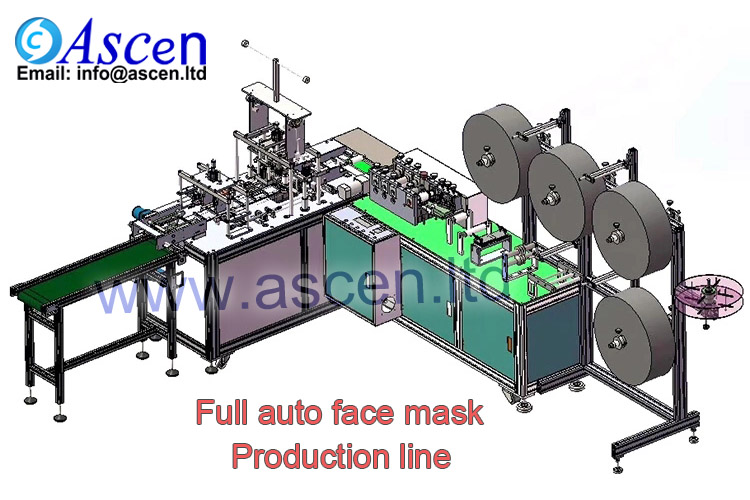

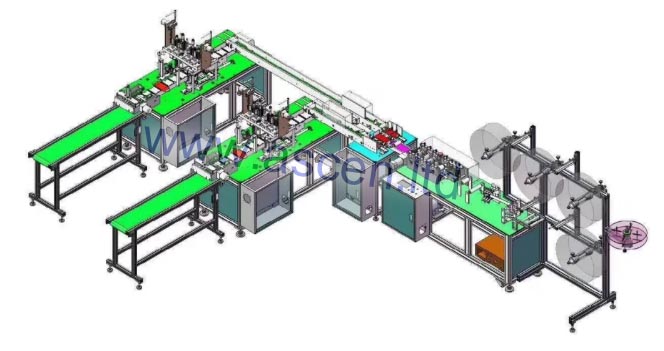

Automation solution 1+1 :HY-C1

Total include:

1 sets of automatic mask manufacturing machine FM series

1 sets of automatic ear loop welding machine FW series

1 sets of automatic face mask transport system

1 sets of conveyor

Room size: 8500*5000mm

Total need 2 operators for loading and unloading

Output efficiency:40-45 PCS/minute

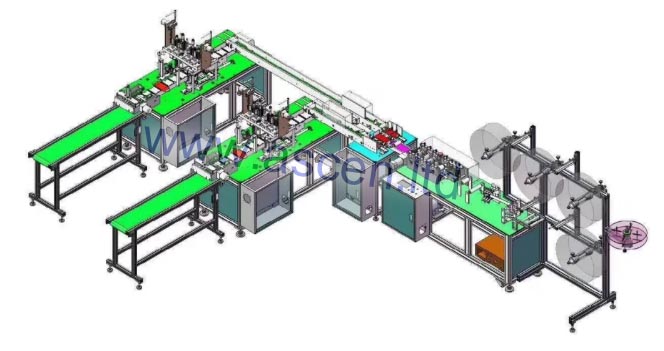

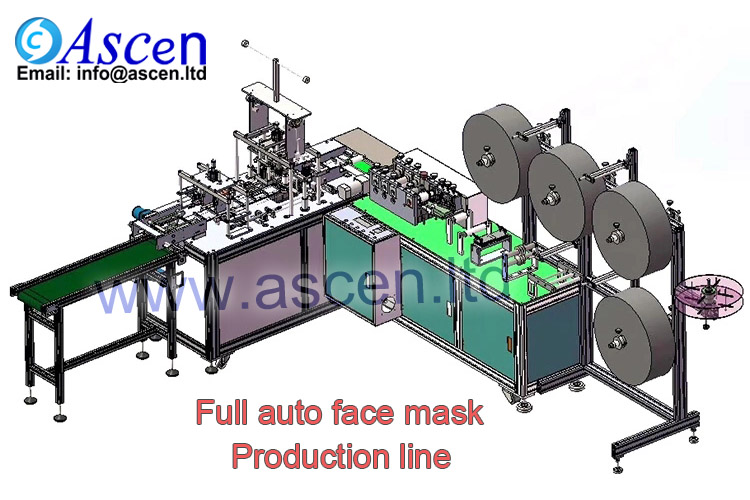

Automation solution 1+2 :HY-C2

Total include:

1 sets of automatic mask manufacturing machine FM series

2 sets of automatic ear loop welding machine FW series

1 sets of double tracking automation face mask transport system

2 sets of conveyor

Room size: 9000*4500mm

Total need 3 operators for loading and unloading

Output efficiency:80-90 PCS/minute

3.Machine feature detail link: https://www.ascen.ltd/Products/mask_making_machine/

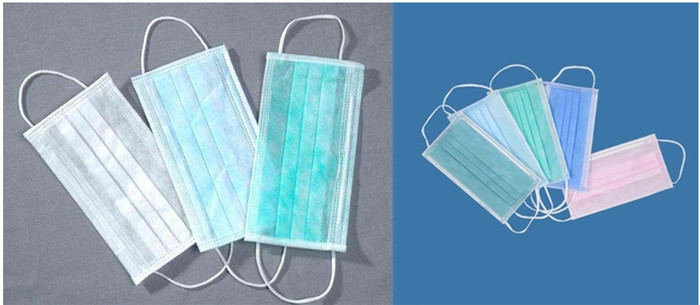

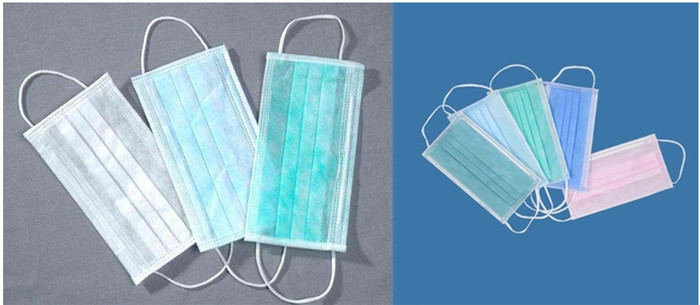

4.Face mask product display:

Multiple layer flat mask include: Non-woven fabrics, Melt-blown fabric(filter paper), Nose bar, ear loop

Mask size: 17.5*9.5cm 15*9cm (Child version)