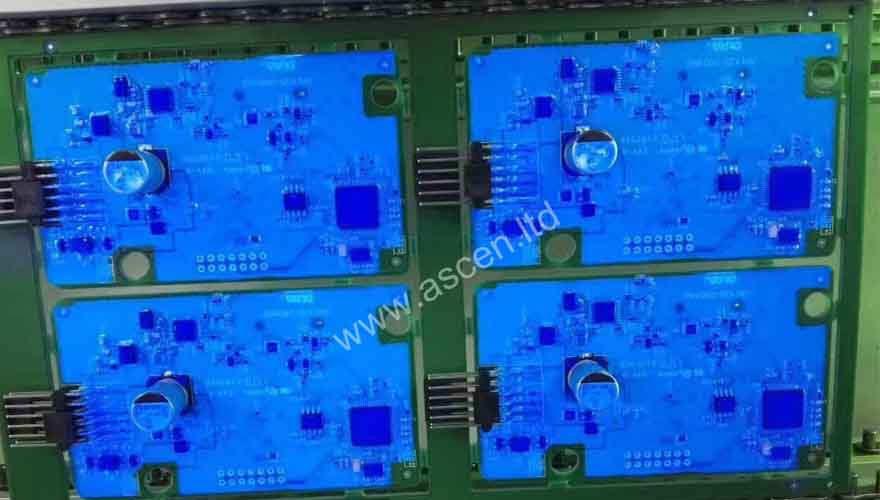

The Selective conformal coating processes solution use for the double layer PCBA intelligent production line.

To finish the PCB protection and keep waterproof dampproof dustproof anti corrosion.

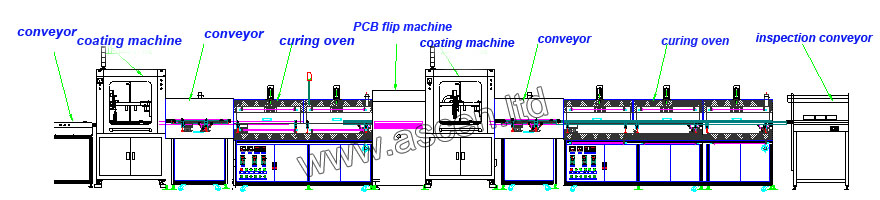

PCB selective conformal coating process direction is left to right

PCB selective conformal coating process direction is left to right

|

Item |

equipment detail and specification |

QTY. |

|

Position 1 |

PCB coating link conveyor(HY-460C)

Size: L1000mm*W740mm*H925mm |

1 set |

|

Position 2 |

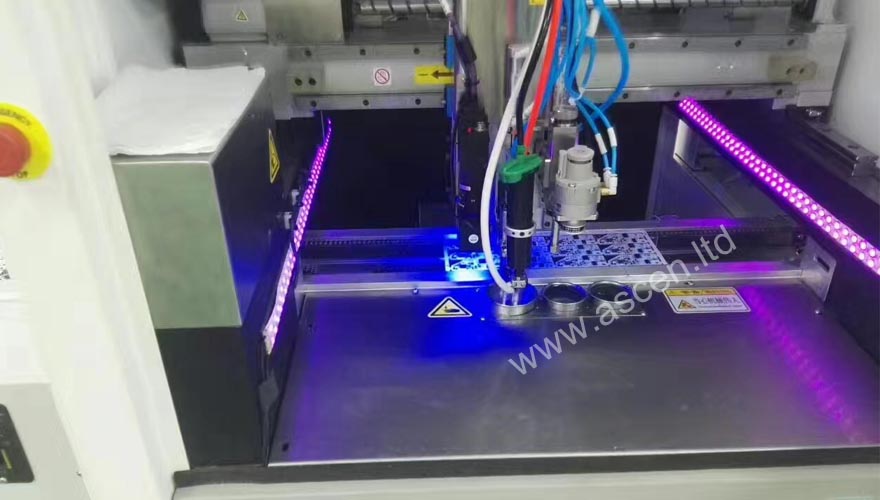

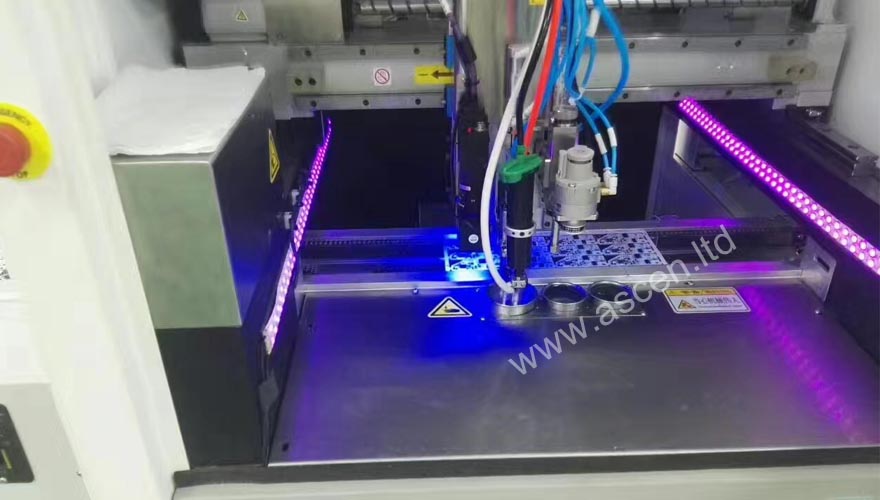

PCB conformal coating machine(AC-450M)

Size: L1000mm*W1100mm*H1650mm |

1 set |

|

Position 3 |

Chain type PCB coating conveyor with UV light(HY-460C)

Size: L1000mm*W740mm*H1230mm |

1 set |

|

Position 4 |

Online PCB curing oven(AO-300A)

Size: L3000mm*W850mm*H1230mm |

2 set |

|

Position 5 |

PCB flip machine (HY-460 inverter)

Size: L600mm*W900mm*H1200mm |

1 set |

|

Position 6 |

PCB coating link conveyor(HY-460C)

Size: L1000*W740*H925mm |

1 set |

|

Position 7 |

Chain type PCB coating conveyor with UV light(HY-460C)

Size: L1000mm*W740mm*H1230mm |

1 set |

|

Position 8 |

Online PCB curing oven(AO-300A)

Size: L3000mm*W850mm*H1230mm |

3 set |

|

Position 9 |

PCB coating inspection conveyor(HY-460C)

Size: L1000mm*W740mm*H925mm |

1 set |

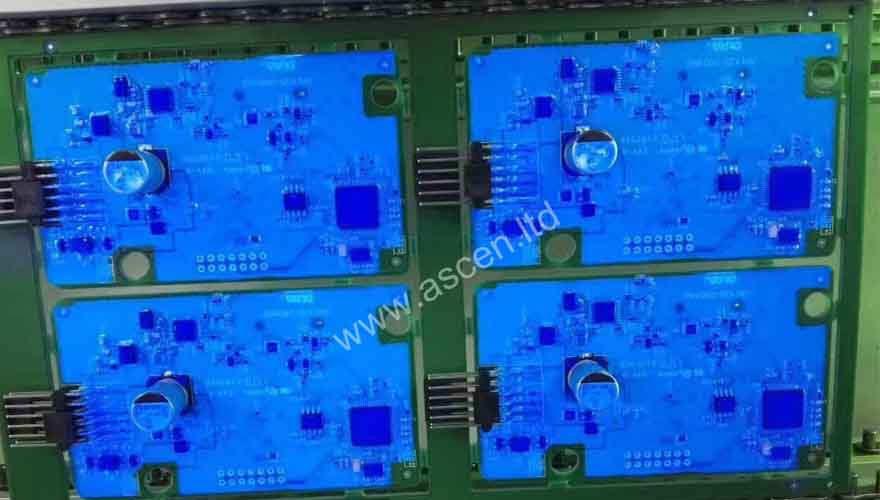

Description of the PCB coating process :

The Operator need place the PCB circuit board to the PCB coating link conveyor,and then output to the PCB selective coating machine, when finish the selective coating, the PCB board will enter the PCB coating conveyor, this is the PCB chain conveyor with the UV light , that is not easy to paste on the three proofing glue after coating, will have better using then the belt type PCB conveyor, pass this PCB conveyor, the PCB board will enter the online curing oven for processing.

When the baking is completed, PCB board will be output to the PCB flip machine/PCB inverter for 360 degree turning, when the PCB into the next PCB coating machine,will start the second layer coating processing, after that the proof glue will cover the PCB board, and then continue into the coating PCB linking conveyor and the PCB curing oven, after that, there is the inspection conveyor on the next station. Will have the operator for checking operation, we also can place the online test equipment here to connect the PCB NG reject conveyor ,it will achieve the automatic inspection to save more labor cost. In the end, the PCB board will be receive by the PCB unloader.

Advantages of the PCB selective conformal coating processes:

automatic selective coating, reduce labor, improve productivity and efficiency, and realize automatic three-proof coating process.