Email:info@ascen.ltd

Skype:supplier889

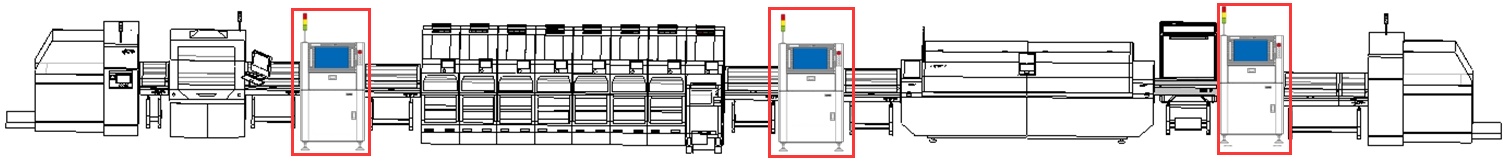

Model:A700

Brand:ASCEN

Delivery Time:28 days

Desciption:

| Functional specifications for ASCEN inline automatic optical inspection machine A700 model | |

| PCB Testing range | Through-hole and hybrid technology of SMT solder,testing PCB after printing, before reflow and after reflow |

| Detection Method | Many leading international algorithms such as TOC, Histograms, Match, Short, OTHER, CREST, PIN algorithms, auto set parameters according to different test dots |

| Camera | High speed individualized digital camera |

| Resolution/Range/ Speed: | (Standard): 15μm/Pixel FOV:38mmX31mm (Speed)<200ms/FOV |

| (Option): 8μm/Pixel FOV:20mmX16mm (Speed)<200ms/FOV | |

| Light | Extra bright RRGB coaxial ring tower LED light (Color light) |

| Program Mode | Manual programming, Auto frame, CAD input automatically correspond to component library |

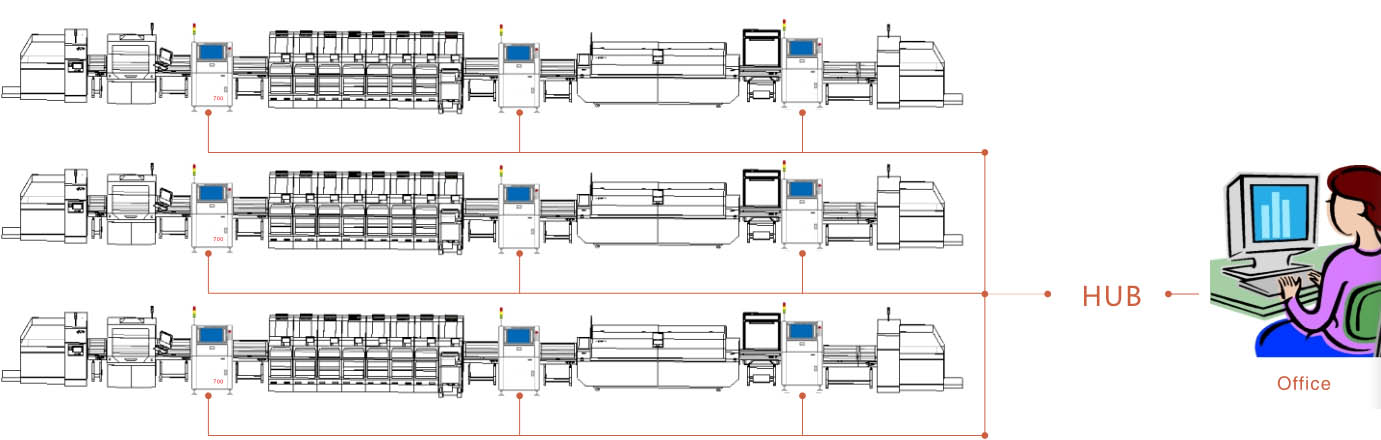

| Remote control | Remote control through TCP/IP. Check, start or stop the machine, or modify the procedures at any time. |

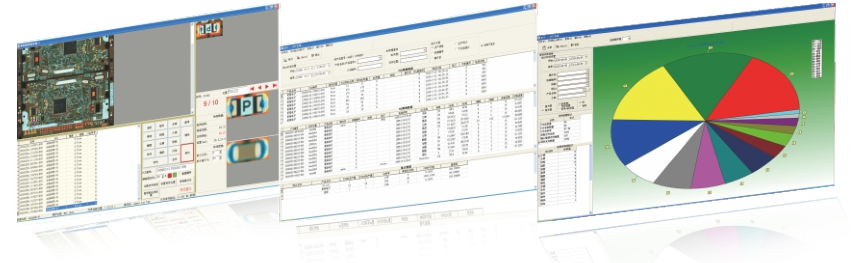

| Inspection Items | Solder printing: Absence presence, misalignment, insufficient, overflow, open, bridge, contamination etc. Component defects: Missing, misalignment, skewed, billboard, mounting on side, overturn, wrong part (OCV), damaged, reversed etc. Solder defects: Overflow, insufficient, pseudo soldering, bridge , contamination etc |

| Special Features | Support auto change program test, multi boards and multi programs test, two sides of programs test |

| Minimum Component &pitch | 8µm:01005 chip &0.3pitch IC |

| SPC and program control | Statistic and analysis of all test data ,check production and quality analysis anywhere, can output Excel, Txt file |

| Bar code System | Camera can read and transfer the Barcode automatically(one-dimension or two dimension) |

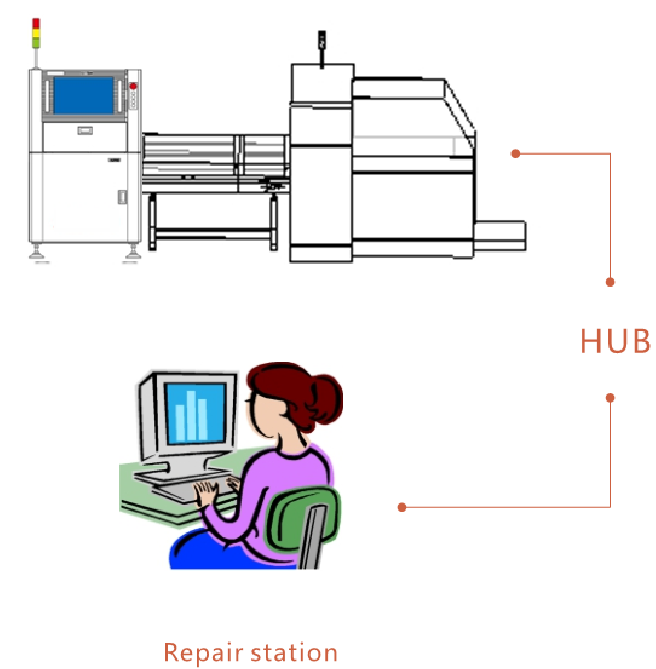

| Server Mode | Administrative data from many AOI through center server |

| Operation System | Windows 7 Professional |

| Display/Output | 22inch TFT LCD, OK/NG signal, send data file to Repair station (Option) |

| System specifications for ASCEN inline automatic optical inspection machine A700 model | |

| PCB size | 50×50mm(Min)~510×500mm(Max) |

| PCB thickness | 0.3 to 5 mm |

| Clamping System Edge Clearance |

TOP:3.5mm Bottom:3.5mm |

| PCB weight | 3KG |

| PCB Tolerance | <5mm or 2% of PCB diagonal length |

| PCB Height | PCB (Top Side): 30mm, PCB (bottom side): 85mm |

| Conveyor | Bottom-up fixed, Automatic compensation to avoid distortion, auto-load and unload, flat belt, adjust the width automatically |

| Conveyor height | 890 to 980mm |

| Conveyor Direction | Left→ right or right→left |

| X/Y Driver | Screw and AC servo driver, PCB fixed, Camera in XY, approved with CTQ |

| Power Supply | AC230V 50/60 less than Hz 0.5KVA |

| Dimension | 900x1300x1565mm ( LxWxH), excluding the height of the signal light,about 700kg |

| Humidity | 10~35 ℃ 35~80% RH ( no dew ) |

| Certificate | According with CE standard |

Whether you'd like to get more info on what,why and how we do what we do, need help with what you're creating,would line to partner up or just say hi!

—--- We'd love to hear from you.

Note : Your information detail will not be published. Required fields are marked*