A10MS model solder dross separator is the off-line independent operation type solder recycling machine,no smoke,tin slag can be centralized treatment,high separation rate,multi-wave soldering machine can share one set of solder dross recovery system,this model with small size,easy to move,manually put tin,with tin car,PCB manufacturers use solder recycling separator to recycle solder onsite directly from their wave solder machines,It can process 120-150kg solder dross in 8 hours.

ASCEN Solder dross separator feature:

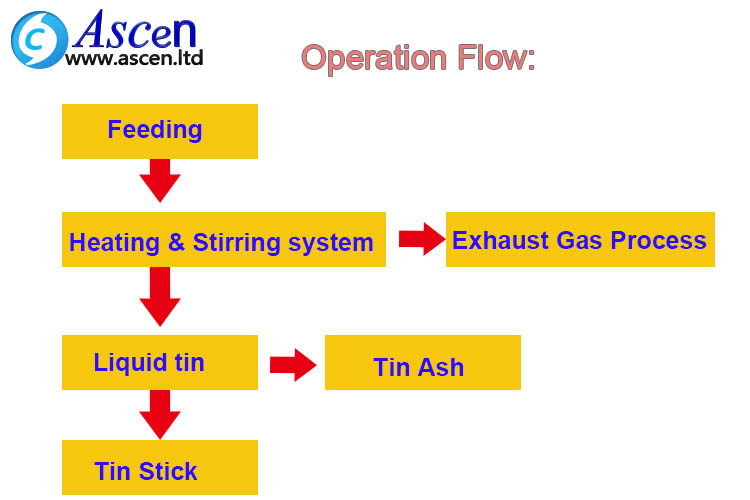

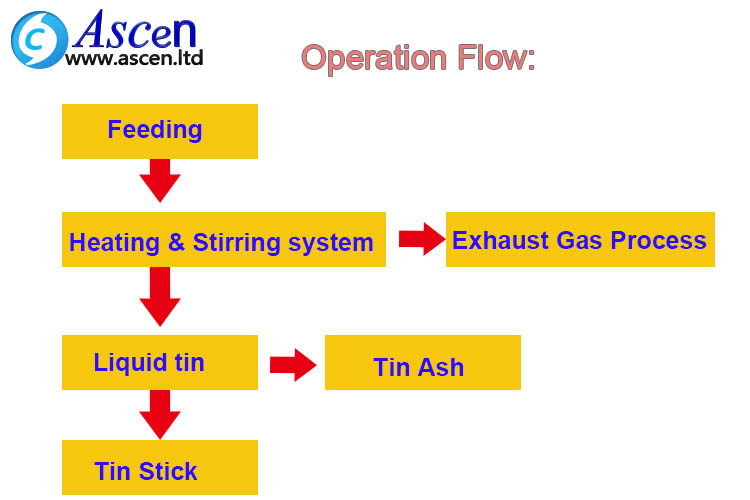

1.Uses special mixing & seperation design,the dross automatically feeded into inner part of mixing part.

2.Automatic separation of tin and tin ash,into the tin and tin-ash collection device.

3.Separated liquid pure tin automatically stored in the tin cabin,when it is reaches a certain volum, the alarm system turns on,operator just only need discharge the liquid pure tin into molding tray.

4.This solder dross separator is no need to clean high temperature filtering cabin to avoid any human damange.

5.The whole solder recycling system total equiped both warm zoon,it can support large capacity tin slag separation, more efficient and faster recovery.

6.ASCEN solder dross separator different from other machine in the market,it updated equiped motor protection device,Effectively prevent damage to the mixing system caused by wrong setting of temperature or other hard metal falling into the machine

7.Updated equiped cooling system,it can help speed up the liquid tin cooling into tin bars.

8.Equipped with smoke filtration system to prevent large particles from damaging the smoke purification system in the plant area.

9.Stability of high separation rate, powder type ash afterater separation hardly see any solder by visual.

10.Suit for energy saving, safty and Econ-friendly requirement.

11.Ability: 120KG-150KG/8H

12.Updated equiped heat insulation prevention mesh controls the machine outside temperature within 45℃,which is avoid operator to be hurt.

|

ASCEN Solder Dross Separator Machine Benefit Forecast Data |

|

|

One midsize solder machine working time |

8 hours |

24 hours(1 days) |

168 hours(7 days) |

720 hours(30 days) |

|

The tin slag output of one solder machine |

3-5kg |

9-15kg |

63-105kg |

270-450kg |

|

The slag recovery output of machine(90%) |

2.7-4.5kg |

8.1-13.5 |

63-105kg |

243-405kg |

|

Cost savings (No lead tin bar average price is 58.8usd/kg |

159-265usd |

476-794usd |

3334-5557usd |

14288-23814usd |

|

Note:in the normal,a ASCEN midsize solder dross separator working 8 hours per day,it can recover the cost of solder dross separator system in a month. |

|

SMT solder dross recovery system specifications:

1.All-stainless steel tank,clean convenience.

2.Power:220V;

3.Machine power :4.3KW;

4.Working Power 1.2KW ;

5.Net weight: Approx 180KG;

6.Dimension:L680*W600*H1120mm

7.Keyboard panel control

8.OmRON temperature meter vertically display temperature adjustment with accurate temperature.

9.Uses PID+SSR for temperature control

10.Uses creepage protection device.

Mixing & Separation System:

1.Feeding gate: ≤10KG dross*2

2.316L stainess steel oven can bear high temperature and rust. Max. 70kg “bottom tin” stored in empty oven, needs 60mins to be melt when uses the machine

3.Uses “U” shape heater covered cast iron heating plate, which is avoid deformation.

4.Patent mixing and separation system.

5.Separation Speed: 15KG /60mins

6.Mixing Motor: 90W 220V

7.Tin Bar/ash: Separated pure tin goes into a cabin,when it reaches a certain volum,the alarm system turns on to inform discharge.Equipped with 2 sets molding tray.Ash goes into collection box, equipped with 2 boexes.

Filtering System:

Outer exhausting gate: 4".